As a kid’s shoe purchasing manager, you know the supply chain for kids’ shoes can be complex.

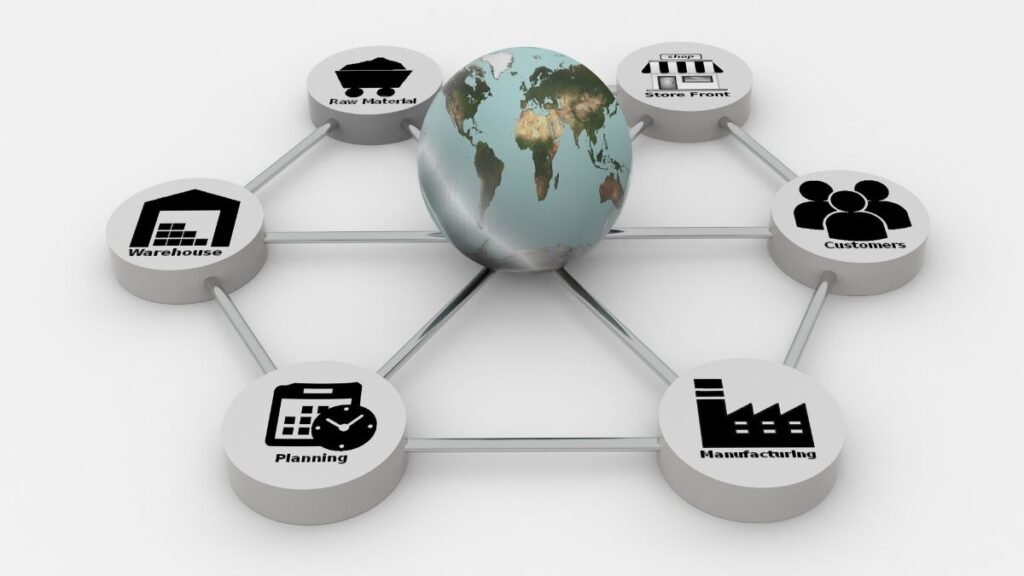

Whether you’re dealing with sourcing products from around the world or managing inventory levels to meet demand, it’s important to have an efficient strategy in place.

One way to maximize efficiency is through vertical integration of your supply chain — integrating different components of production and distribution under one company.

In this blog post, we’ll explore why vertical integration is a great choice for streamlining your kids’ shoe supply chain and discuss its potential benefits.

By taking advantage of these opportunities, you can ensure smooth operations at every step along your supply route — from materials procurement all the way through customer delivery.

I. Understanding the Challenges of Kids’ Shoes Supply Chain

With the ever-evolving supply chain landscape, understanding the challenges of sourcing and delivering kids’ shoes has never been more important.

As one of the fastest-moving consumer goods sectors, footwear for children is subject to some specific trends and obstacles that must be seen as opportunities in order to remain competitive.

Young consumers drive demand for sustainable materials, such as organic cotton and recycled plastic bottles, while responding to pop culture references requiring frequent color and style updates.

Growing feet have their own unique needs, so satisfying a wide array of foot types and fit preferences is critical. It’s no surprise that managing inventory with agility within restrictive lead times can be very challenging.

Despite these unique complexities, harnessing new tools and technologies to create an efficient kids’ shoe supply chain can help companies continue delivering quality products while maintaining profitability.

II. Examining the Benefits of Vertical Integration in Kids’ Shoe Manufacturing

Vertical integration can be a useful way to streamline the production process and make manufacturing more efficient.

This technique is becoming increasingly popular in the world of kids’ shoe manufacturing, as it allows companies to gain advantages such as controlling the supply chain, optimizing both quality and costs and the ability to closely monitor production facilities.

For example, vertical integration allows manufacturers to choose all necessary elements of the production process, such as raw material sourcing, divided tasks within factories, machinery and equipment used for production, marketing, product design, and cost accounting.

By doing this they can ensure that each step of the supply chain meets their needs and helps them achieve their goals.

This ultimately results in a better product for consumers at a lower price.

III. Integrating Technology to Increase Efficiency and Cost-Savings

Integrating technology into business processes is a great way for companies to increase efficiency, save money and reduce their environmental impact. New technologies can help optimize the use of raw materials in manufacturing processes and supply chains, allowing businesses to be more competitive in the market. From improving product design to streamlining communication systems between departments, implementing new technologies enables companies to find cost savings as well as create a strong brand identity. By leveraging technological advancements, companies can improve operational efficiency and profitability throughout the entire organization.

3D printing:

One integrating technology that has been applied in kids’ shoe factories is 3D printing. 3D printing enables shoe designers to quickly and easily create customized designs for shoes, allowing for a more efficient production process. This is beneficial for companies looking to produce limited-edition collections or provide custom-fit options for children with unique foot shapes. Additionally, 3D printing can help reduce the environmental impact of shoe manufacturing, as it eliminates wastage and reduces the amount of energy consumed in production.

Advanced Robotics:

Robots can be used to increase production speed and efficiency, as well as reduce labor costs associated with repetitive tasks in shoe manufacturing.

Automation:

Automating mundane processes in factories helps improve accuracy while reducing the need for manual labor, saving companies both time and money.

Supply Chain Management Software:

With cloud-based software solutions available, businesses can track orders from sourcing materials all the way through the final delivery of products to customers.

By staying up to date on the latest technologies and investing in solutions that are relevant to their business, companies in the children’s shoe industry can increase efficiency, reduce costs, and gain a competitive edge.

IV. Strategies to Automate Quality Control Processes

Automation plays an increasingly important role in quality management processes across all industries.

Implementing strategies to automate quality control processes can boost operational efficiency and help companies achieve the highest standards for product quality.

As an example, many factories that manufacture footwear use automation to manage details and inspections.

This provides detailed reports of any discrepancies that showed up during the inspection process or production runs.

By automating these processes, companies rest assured knowing any errors or defects in their products are flagged automatically and inspected, saving time and money on tedious or manual labor operations.

Automating quality control also improves performance by streamlining operations to increase production, reduce examination costs, and ultimately provide customers with better products that meet their needs.

V. Benefits of a Streamlined Kids’ Shoes Supply Chain

Streamlining the supply chain for children’s shoes provides a myriad of advantages from top to bottom.

For companies and production facilities, vertical integration into the supply chain would allow them to become more self-sufficient.

It also reduces costs due to advancements in technology and knowledge sharing among employees.

This can help keep factories running smoothly, which leads to increased efficiency overall within the supply chain.

With less effort required for production, overhead costs decrease and can ultimately be passed on to customers.

Furthermore, retailers benefit from this streamlining through efficiency gains as well.

Less resources are needed throughout the production process which translates into lower prices and potentially more sales as customers turn to these retailers for discounts on children’s shoes.

Looking at the bigger picture, streamlined kid’s shoe supply chains are more effective at servicing customer needs while providing an encouraging environment that motivates workers and keeps operations safe and profitable.

VI. Implementing Sustainability into the Supply Chain Model

In order to bring about an effective and lasting change to the world, it is integral that companies seek long-term sustainability in the production and management of their supply chains.

This commitment is indicative of a company’s dedication to producing quality materials while also practicing environmentalism.

Companies must be committed to making sure they are both keeping up with current trends and looking ahead to the future by being invested in partnerships that bring greater global sustainability.

Such actions demonstrate a strong belief in the power of businesses to produce changes around the world through responsible production methods and supply chain management.

Taking such steps as integrating sustainability into entry points in production, systems design, and customer engagement is essential for improving our world today and into the future.

Conclusion

With all of these topics in mind, it is clear that there are considerable challenges and opportunities for kids’ shoe supply chains.

Brands, manufacturers, and retailers must show flexibility and a readiness to invest in technology and create partnerships for successful growth in this area.

By understanding the key specialization areas and implementing sustainability into the manufacturing process, companies can reduce costs while increasing the value proposition within their supply chain network.

Furthermore, utilizing vertical integration processes will enable organizations to have more control over production quality and cycle times, as well as provide them with greater agility when dealing with changing customer demands.

Finally by leveraging technology to automate certain quality control processes, not only will operational efficiency improve but risks associated with costly errors or damages may also be reduced.

It is apparent that establishing an efficient; long-term; cost-effective; eco-friendly; and high-performing kids’ shoe supply chain requires significant effort as well as a strategic focus on integrating innovation within the process. H

However, when done correctly it can spark substantial growth opportunities and allow manufacturers to differentiate themselves from competitors who do not have a flexible approach to supply chain management.