As a professional children’s shoe manufacturer, ensuring that our products are of the highest quality and safety is of the utmost importance.

This is why we take the quality final random inspection process very seriously before shipping any shoes to our customers.

Quality control services are essential in the manufacturing of children’s shoes because these products are worn by the most vulnerable group of people, children.

Not only do children’s shoes need to be comfortable and durable, but they also need to meet safety standards and comply with industry regulations.

By thoroughly inspecting each pair of shoes before shipment in our factory, we can ensure that our customers receive only the best quality products that are safe for the little ones to wear.

In this blog, we will take a closer look at the various steps involved in our final random inspection process and explain why they are so crucial in our shoe manufacturing process.

These inspection process steps include:

- Material Inspection: where we check the quality of raw materials used in the shoes and make sure they meet industry standards and safety regulations.

- Design and Construction Inspection: where we review the design and construction of the shoes, check for proper stitching and other construction details and identify any design or construction issues.

- Fit and Comfort Inspection: where we test the fit and comfort of the shoes on various foot sizes and shapes, ensuring that the shoes provide proper support and are easy to walk in.

- Safety and Compliance Inspection: where we check that the shoes meet all relevant safety and compliance standards and are free of any potential hazards.

- Packaging and Shipping Inspection: where we check that the shoes are properly packaged and labeled for shipment and protected during transport.

These steps are all crucial in the final inspection process to ensure product quality before shipment.

It is worth mentioning that these steps are not only useful for the final inspection but also should be conducted throughout the production process to avoid any defects that might occur and make the final inspection process smoother and more efficient.

1. Material Inspection

Checking the quality of materials used in the shoes is a crucial step in the final production inspection. The materials used in the shoes not only affect their durability and comfort but also play a vital role in ensuring the safety of the children who wear them. In order to check the quality of materials used in the shoes, we follow these steps:

- Visual Inspections of the materials used in the shoes: Before starting the inspection process, we review the materials used in the shoes to ensure that they meet the specifications provided by our customers and comply with industry standards and safety regulations.

Check for Defects:

We carefully inspect each pair of shoes for any defects in the materials, such as tears, holes, or discoloration.

Some examples of material defects that we look for include:

- Tears or holes in the leather or synthetic materials used in the shoes.

- Discoloration or uneven color in the materials.

- Weak or frayed stitching.

- Loose or missing embellishments.

- Any other defects or issues that may affect the durability or appearance of the shoes.

- Test the materials: We conduct various lab tests on the raw materials to ensure that they are of high quality. These tests may include stretching, flexing, and abrasion tests to check the strength and durability of the materials.

- Record any issues: If any issues or defects are identified during the inspection process, we document them and take appropriate action to address them. This may include reworking the shoes or replacing the materials used.

By following these steps, we can ensure that the materials used in the shoes are of high quality and meet safety standards, providing our customers with products that are comfortable, durable, and safe for children to wear.

2. Design and Construction Inspection

Design Inspection:

Our product inspectors will inspect the design of each shoe to ensure that it is consistent with the specifications provided by our customers. We check for any issues such as incorrect silhouette, incorrect composition, incorrect high-frequency application, incorrect logo, incorrect colors, and incorrect materials. These are almost critical defects.

Some examples of the specific areas we focus on during this inspection include:

- Silhouette: We check that the overall shape and design of the shoe is consistent with the customer’s specifications. This includes checking that the shoe has the correct toe shape, heel height, and overall proportions.

- Composition: We check that the shoe is made up of the correct materials and colors in the correct proportions. For example, if the customer specified that the shoe should be made of leather with a suede accent, we check that this is the case.

- High-Frequency Application: We check that any high-frequency application, such as embossing or foil, is consistent with the customer’s specifications. This includes checking that the application is in the correct location, size specification, and color.

- Logo: We check that the logo on the shoe is consistent with the customer’s specifications. This includes checking that the logo is in the correct location, size, and color.

- Colors: We check that the colors of the shoe are consistent with the customer’s specifications. This includes checking that the colors are true to life and that there are no discolorations or variations.

Construction Inspection:

Here we check for any issues such as incorrect lasting, incorrect stitching, incorrect lacing, or incorrect gluing. These are almost the major defects.

By conducting a design and construction inspection, we can ensure that the shoes we manufacture and ship to our customers are consistent with the specifications provided by our customers.

3. Fit and Comfort Inspection

Fit Inspection:

The inspector will check the fit of each shoe to ensure that it is consistent with the specifications provided by our customers and that it is the correct size for the child’s foot. We check for any issues such as tightness, or pinching.

Comfort Inspection:

The inspector will check the comfort of each shoe to ensure that it is comfortable for the child to wear. We check for any issues such as rubbing, discomfort, or pain.

Walk Test:

We perform a walk test to ensure that the shoe provides the best possible fit and comfort for the child. We check for any issues such as slippage, discomfort, or pain.

This process will be done before bulk production, but we`ll do it before shipment again to ensure that the shoes we manufacture and ship to our customers provide the best possible fit and comfort for the child’s foot. This step is important in the final inspection process to ensure that our customers are satisfied with their purchase and that the child is comfortable wearing the shoe.

4. Safety and Compliance Inspection

Safety and compliance inspection is an important step in the final inspection process for children’s shoes.

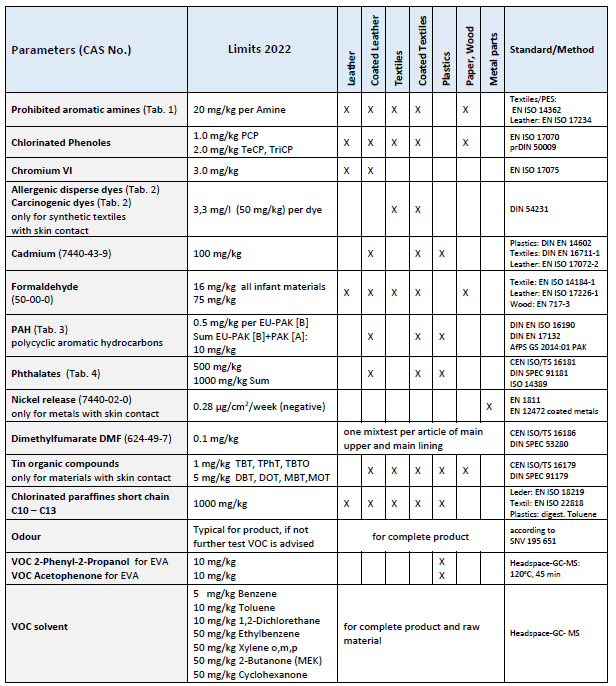

We review industry standards and safety regulations such as ASTM, EN71, and Reach RSL to ensure that the shoes we manufacture comply with these standards.

For example, some major testing items of Reach RSL for children’s shoes include Phthalates testing, Heavy metal testing, Flammability testing, Volatile organic compounds ( VOCs) testing, Azo dyes testing, Carcinogens testing, etc.

By conducting this inspection, we can ensure that the shoes we manufacture and ship to our customers comply with industry standards and safety regulations, which is essential for the safety function of the child wearing the shoe.

5. Packaging Inspection

Packaging inspection is the final step in the final inspection process for children’s shoes. This step involves ensuring that the shoes are properly packaged and prepared for shipment to our customers.

The process of packaging and shipping inspection includes the following steps:

- Reviewing packaging and shipping requirements: We review the packaging and shipping requirements provided by our customers to ensure that the shoes are packaged and shipped according to their specifications.

- Inspecting packaging materials: We inspect the packaging materials to ensure that they are of good quality and suitable for the shoes, including the use of adequate padding and protection to ensure that the shoes are protected during shipment.

- Checking for proper labeling: We check that the packaging is properly labeled with the necessary information such as size and care instructions.

The benefits of packaging inspection before shipment.

- Protection of the shoes during shipment:

By ensuring that the shoes are properly packaged, we can reduce the risk of damage during transportation. This helps to ensure that our customers receive their final products in good condition and are satisfied with their purchase.

- Convenience for Customers:

By conducting a thorough packaging inspection, we can ensure that the shoes are properly labeled and packaged. This can make it easier for our customers to sort and store the shoes, and put them on the shelves more conveniently. This can help to reduce the time and effort required for stocking and selling the shoes, making it more efficient for the customer to sell the final products to the end consumer.

Conclusion

In conclusion, as a professional children’s shoe manufacturer, it is crucial to conduct a thorough final quality inspection before shipment to ensure that the final products we manufacture are of the highest quality and comply with industry standards and safety regulations.

This includes reviewing the quality of the materials used in the shoes, identifying and addressing any defects or issues, and reviewing safety function and compliance standards.

Additionally, conducting a thorough packaging inspection can help to protect the shoes during shipment, increase customer satisfaction, maintain a positive brand reputation, and make it more convenient for the customer to stock and sell the shoes.

Ensuring that these steps are taken in the final inspection process can help to ensure that our customers receive the best possible product and help to build a strong, long-term relationship with them.

If you are a B2B purchasing manager of a shoe brand, we invite you to partner with us as your trusted children’s shoe manufacturer.

Our commitment to high standards quality and compliance is evident in our rigorous final inspection process, and we are dedicated to delivering the highest-quality shoes to our customers.

Contact us today to learn more about how we can help you to provide top-notch children’s shoes to your customers.